Phone Number

+91 73395 44495,

Laser cutting is a technology that uses a laser to slice materials. While typically used for industrial

manufacturing applications. Laser cutting works by directing the output of a high-power laser most

commonly through optics. The laser optics and CNC (computer numerical control) are used to direct the

material or the laser beam generated. A commercial laser for cutting materials uses a motion control system

to follow a CNC or G-code of the pattern to be cut onto the material. The focused laser beam is directed at

the material, which then either melts, burns, vaporizes away, or is blown away by a jet of gas, leaving an

edge with a high-quality surface finish.

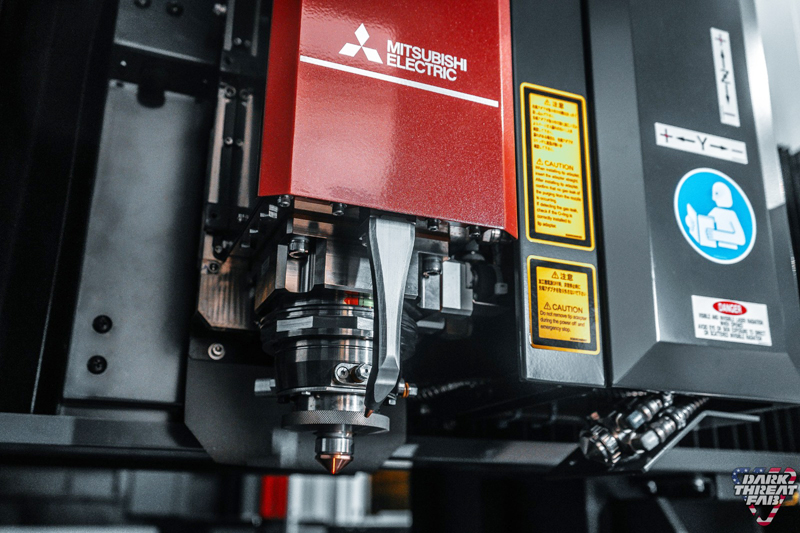

We using Mitsubishi ML3015 Ex and ML3015 SR leading laser cutting machine, which enable us to

cut sheet metal parts of any shape at 100 % repeatability with high quality of edge cut. By using the latest

software allows us to achieve very high accuracy of up to 0.1mm and can utilize our material to the

maximum extent and optimize the laser cutting process with less material wastage.

| Cutting Area | : | 3000x1500mm |

| Maximum Power | : | 3200 Watts |

| Mild steel | : | up to 20mm |

| Stainless steel | : | up to 12mm |

| Aluminum | : | up to 12mm |

| Acrylic | : | up to 25mm |